Product Description:

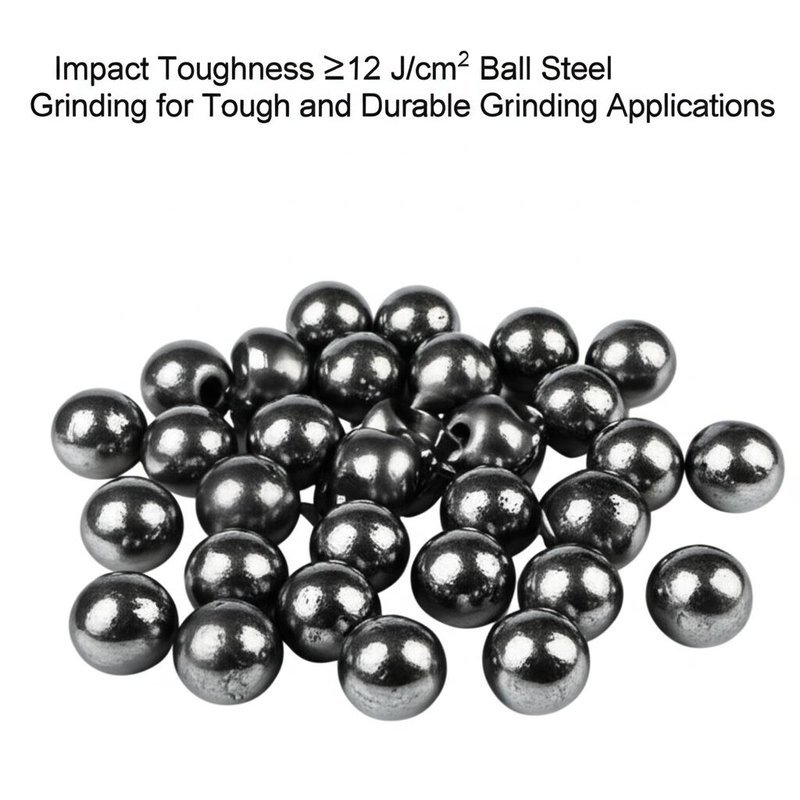

The Ball Steel Grinding product offers high-quality steel balls designed for various grinding applications. These steel balls are essential components in industries such as mining, cement plants, power stations, and more. With a focus on durability and performance, these Steel Grinding Balls are manufactured using advanced production techniques and stringent quality control measures.

Testing Equipment: The Grinding Steel Balls undergo rigorous testing using state-of-the-art equipment to ensure superior quality. The testing equipment includes a Hardness Tester and Chemical Analyzer, which are used to assess the hardness and chemical composition of the steel balls. This ensures that the product meets the required specifications and standards for optimal performance.

Production Line: The steel balls are produced using a specialized Forging and Rolling production line. This process ensures that the steel balls are forged and rolled to precise dimensions and specifications, resulting in high-quality and consistent products. The forging and rolling techniques used in the production line enhance the strength and durability of the steel balls, making them ideal for heavy-duty grinding applications.

Surface: The Grinding Steel Balls feature a sleek Black surface finish, providing both aesthetic appeal and corrosion resistance. The black surface finish not only enhances the visual appeal of the steel balls but also protects them from environmental factors, ensuring long-lasting performance and durability.

Impact Toughness: The Grinding Steel Balls exhibit excellent Impact Toughness, with a minimum value of ≥12 J/cm2. This high impact toughness ensures that the steel balls can withstand the rigors of grinding applications, including high-impact and abrasive conditions. The superior impact toughness of the steel balls contributes to their longevity and efficiency in grinding processes.

Hrc: The steel balls have a hardness rating of Hrc 58-64, indicating a high level of hardness and wear resistance. The Hrc rating ensures that the steel balls maintain their shape and hardness even under extreme grinding conditions, providing consistent performance and efficiency. The hardness rating of Hrc 58-64 makes the steel balls suitable for a wide range of grinding applications across various industries.

Overall, the Grinding Steel Balls product is a reliable and high-performance solution for grinding applications requiring durable and efficient steel balls. With advanced testing equipment, a specialized production line, a black surface finish, excellent impact toughness, and a high Hrc rating, these steel balls are designed to meet the demanding requirements of industrial grinding processes.

Features:

-

Product Name: Grinding Steel Balls

-

Application: Mining, Cement Plants, Power Stations, Chemical Industry

-

Microstructure: M+C

-

Raw Material Heating: By Electric Furance

-

Temperature Of Media: 260℃

-

Impact Toughness: ≥12 J/cm2

Technical Parameters:

|

Breakage

|

<1%

|

|

Microstructure

|

M+C

|

|

Core Hardness

|

45-60HRC

|

|

Hrc

|

58-64

|

|

Testing Equipment

|

Hardness Tester, Chemical Analyzer

|

|

Raw Material Heating

|

By Electric Furance

|

|

Application

|

Mining, Cement Plants, Power Stations, Chemical Industry

|

|

Impact Toughness

|

≥12 J/cm2

|

|

Surface

|

Black

|

|

Temperature Of Media

|

260℃

|

Applications:

Steel Ball Grinding is a crucial process in various industries, and ZW's Grinding Steel Balls are designed to meet the demanding requirements of different applications. With models including B2, B3, C45, and 60Mn, these steel grinding balls are versatile and suitable for a wide range of scenarios.

Manufactured in China, these grinding steel balls from ZW come with ISO9001:2008 certification, ensuring quality and reliability. The minimum order quantity for these products is 10 tons, and the price is open for negotiation, making them accessible for different business needs.

When it comes to packaging, customers can choose between container bags or steel drums based on their preferences. The delivery time for orders typically ranges from 1 to 3 weeks after the advance payment, providing efficiency and timely supply.

Payment terms for these steel grinding balls include T/T and L/C, offering flexibility for buyers. ZW boasts a supply ability of 80000 tons per year, ensuring a steady and reliable source of these essential products.

With a microstructure of M+C and a breakage rate of less than 1%, these grinding steel balls are durable and efficient in various environments. The Hrc range of 58-64 further enhances their suitability for demanding applications in mining, cement plants, power stations, and the chemical industry.

For quality assurance, ZW provides testing equipment such as hardness testers and chemical analyzers to maintain consistent product performance. Whether for high-impact mining operations or precise cement grinding processes, these steel grinding balls are designed to deliver exceptional results.

Customization:

Product Customization Services for Ball Steel Grinding Balls:

Brand Name: ZW

Model Number: B2 B3 C45 60Mn

Place of Origin: China

Certification: ISO9001:2008

Minimum Order Quantity: 10 tons

Price: Negotiation

Packaging Details: container bags or steel drums

Delivery Time: 1-3 weeks after the advance

Payment Terms: T/T ,L/C

Supply Ability: 80000 tons per year

Testing Equipment: Hardness Tester, Chemical Analyzer

Impact Toughness: ≥12 J/cm2

Application: Mining, Cement Plants, Power Stations, Chemical Industry

Raw Material Heating: By Electric Furnace

Breakage: <1%

FAQ:

Q: What is the brand name of the grinding steel balls?

A: The brand name of the grinding steel balls is ZW.

Q: What are the model numbers available for the grinding steel balls?

A: The model numbers available are B2, B3, C45, and 60Mn.

Q: Where is the place of origin for the grinding steel balls?

A: The grinding steel balls are manufactured in China.

Q: What certification does the grinding steel balls product have?

A: The grinding steel balls are certified with ISO9001:2008.

Q: What is the minimum order quantity for the grinding steel balls?

A: The minimum order quantity for the grinding steel balls is 10 tons.

Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten!

Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten! Bitte überprüfen Sie Ihre E-Mail!

Bitte überprüfen Sie Ihre E-Mail!  Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten!

Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten! Bitte überprüfen Sie Ihre E-Mail!

Bitte überprüfen Sie Ihre E-Mail!